The Best Guide To Motorcycle Parts New Zealand Specialists

Wiki Article

Little Known Facts About Motorcycle Parts New Zealand Specialists.

Table of ContentsAn Unbiased View of Motorcycle Parts New Zealand SpecialistsThe Ultimate Guide To Motorcycle Parts New Zealand Specialists8 Easy Facts About Motorcycle Parts New Zealand Specialists DescribedFascination About Motorcycle Parts New Zealand SpecialistsLittle Known Questions About Motorcycle Parts New Zealand Specialists.The Best Guide To Motorcycle Parts New Zealand SpecialistsOur Motorcycle Parts New Zealand Specialists DiariesThe 6-Minute Rule for Motorcycle Parts New Zealand Specialists

So, get to out to one of our professionals today.CNC machining innovation is promptly coming to be the centerpiece of various manufacturing procedures around the world as a straight outcome of its numerous advantages over other techniques. In addition, the industries that manufacture bikes have jumped on board with this pattern. One of the most ingenious firms are now developing their engine parts and wheels making use of machining techniques originally developed for motorcycle parts.

You might be asking yourself why we use. Currently that we have your interest allow us clarify the reasoning behind this modern advancement in the motorcycle manufacturing market.

See This Report about Motorcycle Parts New Zealand Specialists

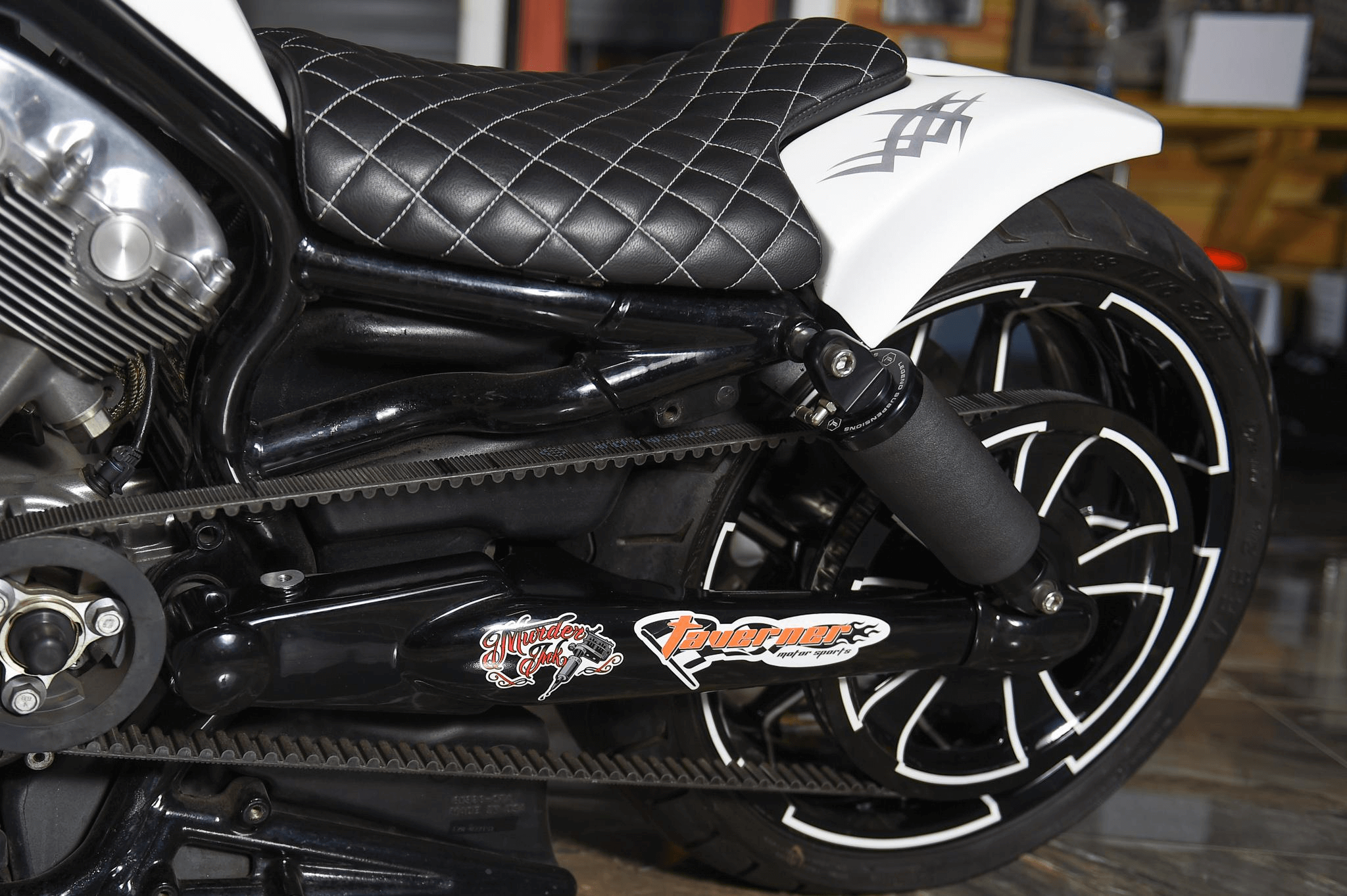

In addition, you have total control over the look of the elements, even down to the minute details. Sometimes, motorcyclists may choose to spruce up their adventure by installing aftermarket elements or customizing the bike's makeover.

4 Simple Techniques For Motorcycle Parts New Zealand Specialists

CNC machining may be used to make virtually all of a bike's steel and plastic parts. To proceed, we'll review several machined parts for motorbikes.Milling procedures are utilized to obtain the desired level of wheel customization. One more aspect of the bike that may be individualized is the tires.

Our Motorcycle Parts New Zealand Specialists Statements

When it concerns a lorry (or a motorcycle), the most important element is the engine. Numerous individuals suggest to it as the "heart" of the vehicle. On the other hand, the camshaft, the cyndrical tube head, and the pistons often tend to be intricate and require layouts with a high level of accuracy.Lights is an additional complicated element of customization. Use only high-quality products, nevertheless, since these lights are critical for the safety and security of motorcyclists and other chauffeurs or individuals on the road, specifically at evening. Bike fronts lights have 3 almosts all: the light bulb, or light, the lens, and the real estate. In particular, we customize the lens and the real estate.

Milling procedures with a perfect surface would lead to the lenses having a reflective top quality that resembles that of a mirror. The cover, on the various other hand, is not made up of breakable products; instead, it is constructed out of hard polymers that can be machined right into more elaborate patterns.

The Buzz on Motorcycle Parts New Zealand Specialists

They often have fancy geometries with a riches of minute details. Bike suppliers typically cast these elements, but only for the production of bespoke parts. CNC machining is the technique of selection when creating unique items. Machining on 5 axes in today's world is the means whereby any type of design form might be recognized.Pick Runsom for your customized bike parts! We have the capacity to fabricate complex and trendy parts making your motorbike incomparable.

Right here are a couple of instances of metals frequently utilized in motorbike element machining. Light weight aluminum is the key material made use of by business concentrating on creating custom-made motorcycle elements to develop a lot of these components. In the past, we would certainly construct our engines out of actors iron. On the other hand, light weight aluminum is swiftly becoming the product of option, partially because of the reality that it is more light-weight.

Zinc refers to an additional steel that is very light in weight and has great machining high qualities due to its high mechanical toughness. This product might be developed into virtually any kind of form and maintains its measurements well. Even mission-critical parts that require a high level see post of precision may benefit from their use.

Motorcycle Parts New Zealand Specialists Can Be Fun For Everyone

One more steel that sees heavy usage in the production of CNC-customized components is magnesium. It is among the lightest steels that are now obtainable and has exceptional machinability functions and toughness commensurate with its reduced weight. One of the drawbacks of magnesium is that its dirt may easily catch fire.

Due to its superior machinability and weldability, stainless-steel is an alloy that is specifically fit for CNC processes. They have fantastic deterioration resistance and a high aesthetic charm. Their most typical usage in creating different motorbike elements is fasteners, such as screws and screws. Their reduced sensitivity to oxidation and rust makes them suitable for this usage.

Get This Report about Motorcycle Parts New Zealand Specialists

It appears that CNC turning and grating are the foundational procedures. Alternate techniques exist, such as boring. Allow's explore a number of these machining strategies detailed. The CNC turning method is considered a subtractive production method. Additionally, it requires keeping bars of material, most frequently plastic or metal, ready and then twisting a reducing tool to remove areas of the product as the Full Report material is transformed.

These approaches are just as crucial and produce components with high precision and consistent quality. The procedures help improve the total high quality of the machined motorcycle components.

Motorcycle Parts New Zealand Specialists for Beginners

Report this wiki page